Once, one of my acquaintances, Dmitry, the director of a med-size, diversified holding, asked for an opinion on the processes. He was interested in how justified the application of processes in business.

I began my answer with the traditional theoretical basis. It is a modern approach, which allows to direct resources to the product in the most rational way, their description, both in the database and on paper, helps to better understand and optimize the business, etc. However, at that moment, I remembered a rather vivid image of what the processes look like in reality.

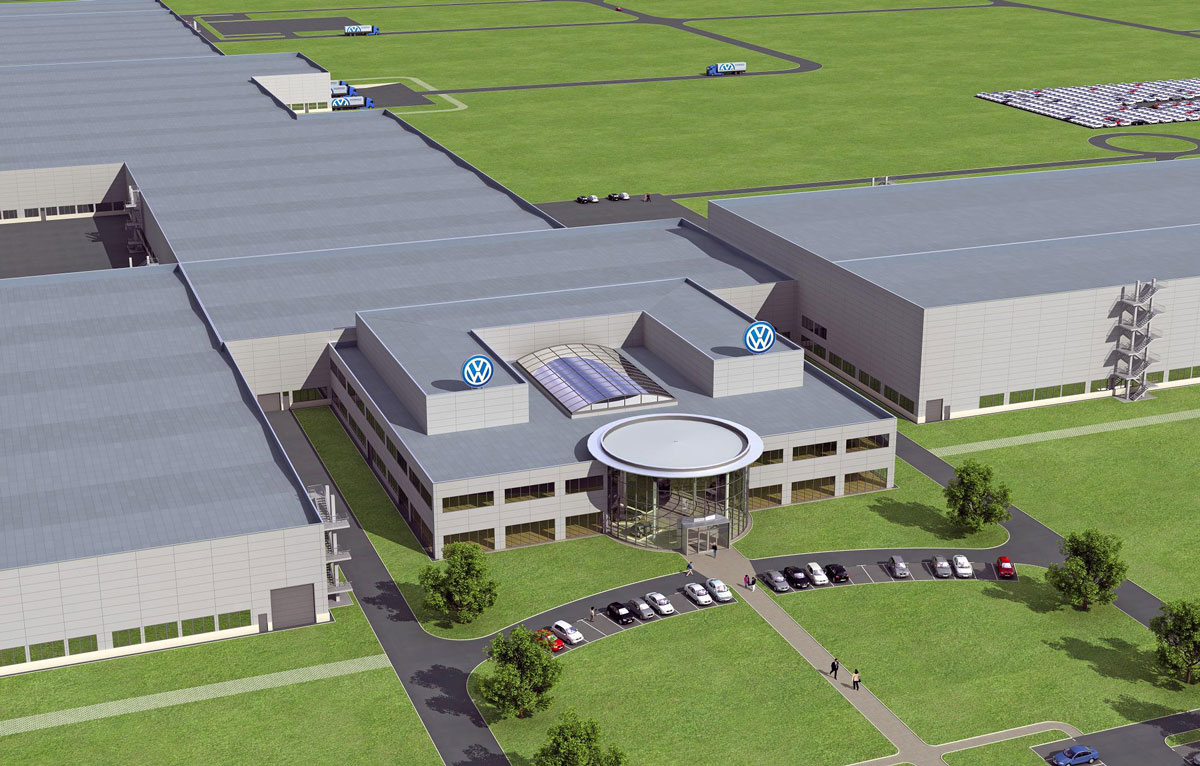

Once on the matters of my practice, I visited a newly built car factory of Volkswagen groups in Kaluga. On the occasion, I was given a tour of its workshops. That’s where I had the opportunity to observe the processes live.

The conveyor ridge bizarrely wriggled at the level of the ground floor, then quickly climbed to the next level, and sometimes even lost over the slabs and invisibly flowing into a nearby shop. It is hard to believe that only a hundred years ago Ford first used the conveyor for the production in a single stream.

Processes are small streams and rivers, originating from an event and ending with lakes and seas, where they carry their results. In this case, the stability of the result, i.e. the product that the consumer needs, affects the accuracy of all operations in the process. Remember the famous “Who sewed the buttons? Raikin (https://en.wikipedia.org/wiki/Arkady_Raikin)? Standardized and stable processes are a good way to get a product with predefined properties. All quality systems are built on these principles: ISO9000 series standards, Six Sigma, Lean Manufacturing, etc. It is the optimally designed and correctly constructed processes that allow you to obtain products that, according to the strategy, will lead to the planned long-term goals.

The standard shop floor for mustered-out cars in the Russian Volkswagen had to be slightly expanded, moving the auxiliary facilities. On the one hand, this indicates a slightly worse quality of the new conveyor (I hope that’s only for now, since it is loaded only about 5% due to adjustment). On the other hand, it has a powerful and effective system of quality control. Otherwise, all machines with defects would be simply imposed on the dealers and sold. In favour of the quality control speaks local anecdote, when about a hundred and a half colourful Tiguanas returned to the plant from the site of the finished product due to defects in painting, obliging the average management (which are entitled to a company car) to drive them daily. According to the plan of the Germans, it should cause a feeling of embarrassment for the defects every day, contribute to greater zeal and encourage caring more about quality.

Many companies have traditionally grouped processes by organizational attributes. This deprives them of flexibility and makes it quite difficult (if not impossible) to proper use some necessary managerial tools:

- Relationship to strategy, i.e. long-term business existence

- Their execution, i.e. coordination with other processes

- Regulation, i.e. stability and quality

With a bit of irony you can try to imagine the work of a conveyor based on organizational units: here in a corner, there is a tire fitting service with summer and winter tires departments; along the wall, there is a department for plastic parts, and right in the center of the shop – the department of metal components.

However, the irony can easily turn into sarcasm if we remember how many companies are organized based on departments. It is terrible to imagine what would happen, start different departments, divisions and offices on the conveyor belt to fight for their importance to a company, inflating their status.

Uniqueness is not in the whimsicality of the process, but in its comprehensibility and some peculiarities, including technological, of its parts. For example, on the same Volkswagen factory there are examples of an execution of a process’s unique parts. However, no one can think of distinguishing them from the total number of works performed on the conveyor, and somehow encourage them additionally. Moreover, these procedures usually fully automated.

Probably the most amazing fully mechanized procedure at the factory is the coupling of a body and an assembled in a single piece suspension. In the local slang, it is called “marrying”. Imagine how many points you need to combine on two previously assembled structures and you’ll get a feel for the complexity of the engineering solution. I would like to add that all the cars assembled at the factory – both SUVs and compacts, both Volkswagen and Skoda, – are being “married” on a single apparatus, and the conveyor belt will feed different bodies alternately. That is, just “married” Tiguan, followed by Octavia, etc. All this without human intervention.

Another unique procedure is laser welding of the car roof with the sides of the body. If you pay attention to the products of Volkswagen groups (Audi, Volkswagen, Skoda) there are no rubber lengthways strips on the roof, which cover the places of contact welding at other maker’s car plants. The laser welding machine makes a single flat seam, not subject to corrosion and more securely fastens the body elements. This machine is unique, made customized by request and quite expensive in operation – out of 50 kW of energy consumption about only four goes to the welding itself, the rest are cooling, ventilation and mechanical support, because the procedure performed in a closed box without human intervention. You can watch the operation through special TV monitors.

Adding value to the final product at each stage is the basis for process design. All other functions only burden the product with additional costs and, as a result, lead to lost profits or, in some cases, loss of competitive advantage.

Process design is not only possible, but also very useful for business. In fact, it is the only way to organize a complex business, where there are many business lines with numerous products. This is the way to focus the business on the consumer, who, choosing a product (or service), will evaluate the quality of the result with their money and contribute to the growth of business. You just need to be more careful with their automation, because this thing is costly, and not always well done.

Remembering a visit to the Volkswagen, sometimes I am surprised by the fact that in a few years a fully operational plant was built in a clean field. And almost immediately it started producing high-quality German cars. Moving through the workshops, I had a chance to observe sensible and slightly concerned eyes of infrequent workers, which gives hope for the success of this project.

P.S. Special and great thanks to Mikhail, who walked me through the workshops and showed (and told in detail!) about the peculiarities of production, demonstrating enormous knowledge of details.

Leave a Reply